Machining cutting insert VNMG CNMG WNMG CNMG TNMG Indexable Carbide Turning Insert - OPM series

Description

Low Cobalt content, and high cubic content carbide substrate combine with thick TiCN and , treated with special after Al2O3 coating, which increases wear resistance. Preferred grade for semi finishing to finishing steel machining.

Additional information

| PMK | P10 |

|---|

| Grade | OC2125 |

|---|

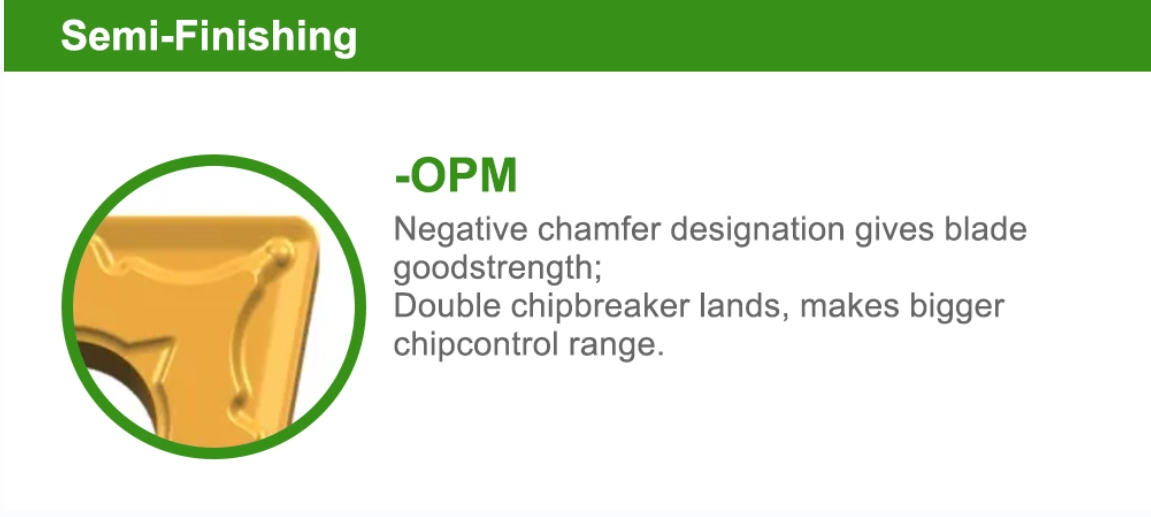

| Chipbreaker | OPM |

|---|

| Chipbreaker Description | Semi-finishing chipbreaker for steel machining. Negative chamfer designation gives good edge strength. Double chipbreaker lands allows for larger chip control range |

|---|

| Brand | OKE |

|---|

*The preferred chip-breaker for semi-finishing of steel materials.

*With the negative chamfering design on the cutting edge, the blade has excellent edge strength and supreme impact resistance.

*Excellent chip-breaker design brings wider chip breaking range, the best chip breaking range is Fn: 0.2- 0.35mm/r.

*The primary application is semi-finishing of steel materials, and light interrupted machining of steel materials.

The carbide inserts is one type of well commented carbide turning inserts which be popular among our customers all over the world.

1. 100% original carbide powder and excellent wear resistance and toughness;

2. High performance of CVD/PVD coating, with super hard and smooth surface;

3. ISO9001:2015 quality system control;

4. Professional chip-breaker design and provides perfect cutting performance;

5. Precise dimension, high accuracy;

6.Super long and consistent tool lifespan;

7. Customized insert design, coating, marking, packing are available.

Advantages:

1.100% factory price and good quality

2.High stability, high performance,longer service life

3.Have in stock, fast delivery

Feature:

1.Excellent wear resistance and breakage resistance

2.Professional inspection and high precision

3.High precision, easy replacement, general use